Morakniv Food Industry

Our Morakniv brand manufactures and sells a wide range of high-quality knives for the professional food industry. Each model is developed for specific tasks in slaughterhouses, restaurant kitchens and charcuteries, ensuring high quality in every cut. The knives are produced in our factory in Mora, Sweden, using carefully selected Swedish stainless steel with a recycled ratio exceeding 90%.

Designed with safety, hygiene and performance in mind, every detail is considered – from the ergonomic handle that provides a secure grip, to the flexible blade that reaches every part of the meat. The knives help prevent repetitive strain injuries, and the high-quality steel allows for long periods of efficient work without frequent sharpening.

All manufacturing runs on 100% green electricity, and our knives are certified according to NSF standards (US National Sanitation Foundation). With Morakniv, you get proven functionality, responsible production and tools trusted by professionals worldwide.

The Steel

The Swedish stainless steel from Alleima in Sandviken has been part of our knives for over a century – a hallmark of quality ever since. Over time, the share of recycled content in the steel has steadily increased. Today, the alloy is made from 80–90% recycled Swedish stainless steel.

In modern steel production, it’s rare for stainless steel to be made entirely from virgin material. Research shows that recycled steel retains the same high quality, and since iron atoms are eternal, the material can be reused indefinitely in new compositions. As a result, most stainless steel products worldwide are made from recycled sources. Increasing the recycling rate also reduces carbon dioxide emissions – a key factor in more sustainable manufacturing.

Our knives feature a micro grain steel structure that allows for a finer, sharper edge with minimal tearing – ideal for high-precision tasks. To enhance durability and edge retention, each blade undergoes an industryleading cryogenic hardening process, resulting in a Rockwell hardness of 58 HRC. This not only extends the time between sharpening but also increases resistance to chipping and cracking, even when cutting harder materials like bone or frozen foods.

The blade then receives its final shape through computer-controlled spine, side and edge grinding, ensuring optimal geometry and consistent performance. Robotically sharpened for precision, each blade is tested and documented to guarantee uniform sharpness and maximum efficiency. Finally, a mirror-polished finish reduces friction, improves glide, simplifies cleaning and minimizes bacterial buildup – essential for hygienic handling and NSF-certified equipment.

Despite the name, stainless steel is not fully resistant to corrosion. A more accurate term would be rustresistant steel. All steel is sensitive to corrosion, but our stainless steel blades are made to offer exceptional strength, durability and better rust resistance in wet or moisture environments.

It’s all about the grip

How a knife feels in your hand is crucial. That’s why our four handle types are developed with your work in mind. Our top priority is to ensure that you can perform your tasks with power, precision and full control – safely and efficiently.

Each handle is designed for a specific area of use, with different materials and colors to suit the varied demands of your workplace. The handles on our food processing knives are ergonomically shaped to allow strong, precise and controlled movements, helping reduce the risk of repetitive strain injuries.

We offer four distinct handle materials, each serving a specific purpose: Ergonomicgrip, G-Grip, Unigrip and Progrip.

Custom colors are available on request.

Handles

Grips

The Blades

Morakniv’s industrial food knives combine advanced metallurgy and precision engineering to ensure durability, versatility, sustainable cost-efficiency and compliance with food safety standards. When developing new products, we are guided by the evolving requirements of the food industry to consistently provide optimal knives where efficiency is key.

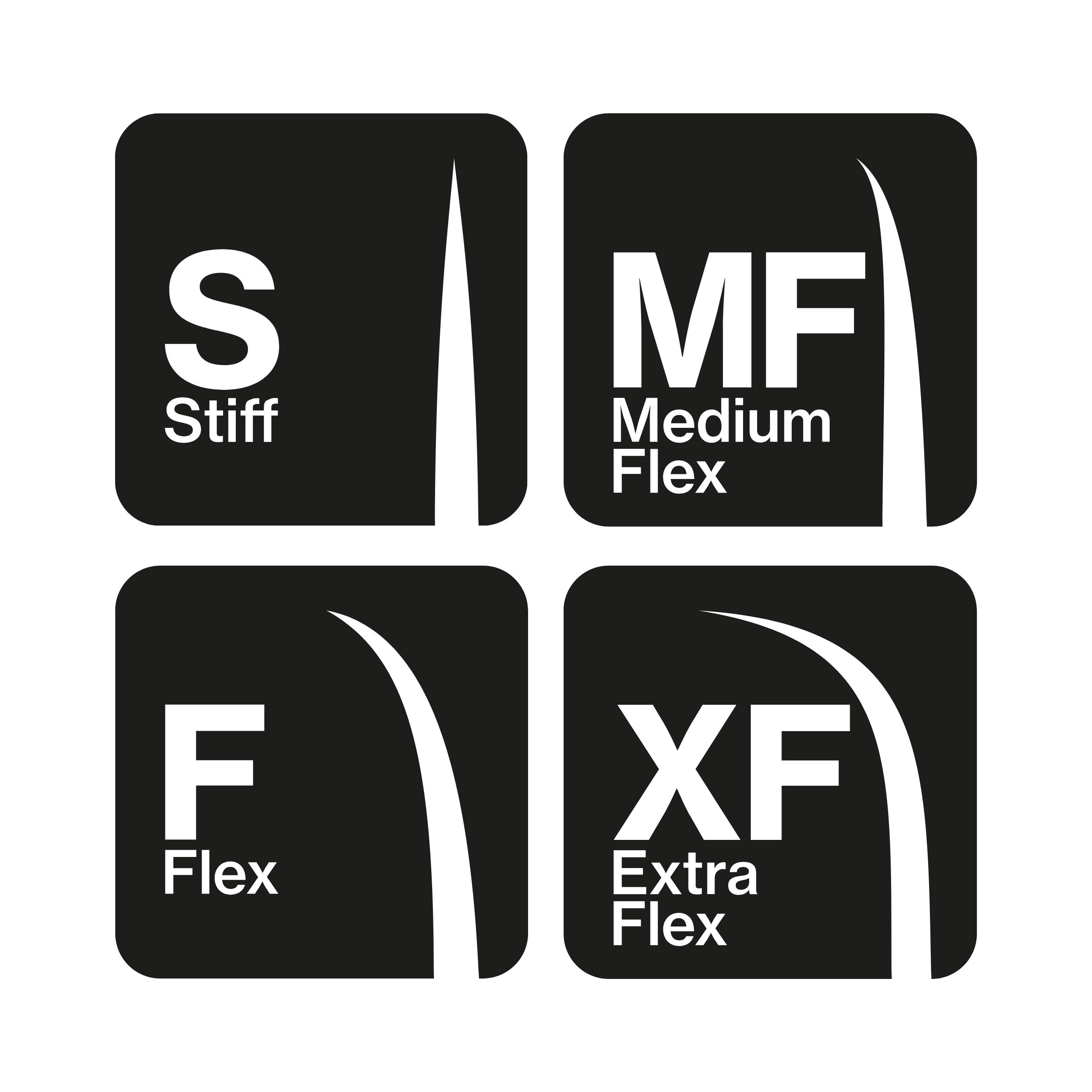

- Stiff Blade – Strong Blade for maximum control and durability.

- Medium Flex Blades – Versatile, suitable for a wide range of tasks, good control, adaptable to various cutting needs.

- Flexible Blades – for precise tasks, perfect for filleting or precise deboning, enhanced manoeuvrability, easy to cut around bones and joints.

- Extra Flexible Blades – highest precision, for fine filleting and maximum manoeuvrability, highest level of flexibility makes it easy to use for most precise tasks.

Four flexibility grades – versatility for every application

Our blades are available in four flexibility grades, allowing them to adapt to a wide range of cutting tasks:

• Stiffer blades excel in heavy-duty applications such as bone-in meat processing or slicing dense vegetables, offering precision and maximum durability.

• Flexible blades are ideal for delicate work like filleting and deboning, where maneuverability around bones and joints is critical.

This adaptability reduces the need for multiple specialized knives, streamlining workflows and cutting overall costs.

Cryogenic Hardening for enhanced durability and edge retention

Our cryogenic hardening process results in a Rockwell hardness of 58 HRC, significantly improving blade performance:

• Increased hardness: ensures superior edge retention, reducing the need for frequent sharpening and replacement – allowing you to work longer with less effort.

• Improved toughness: minimizes internal stresses in the steel, enhancing resistance to chipping and cracking, even when cutting hard materials like bone or frozen foods.