Grinding is one of the most important steps in knife manufacturing – no matter how precise the heat treatment is, a knife will never be better than its edge. At Morakniv we have sharpened knives for generations, from hand-grinding on large whetstones to today’s CNC-controlled robot-equipped grinding cells that guarantee the highest precision.

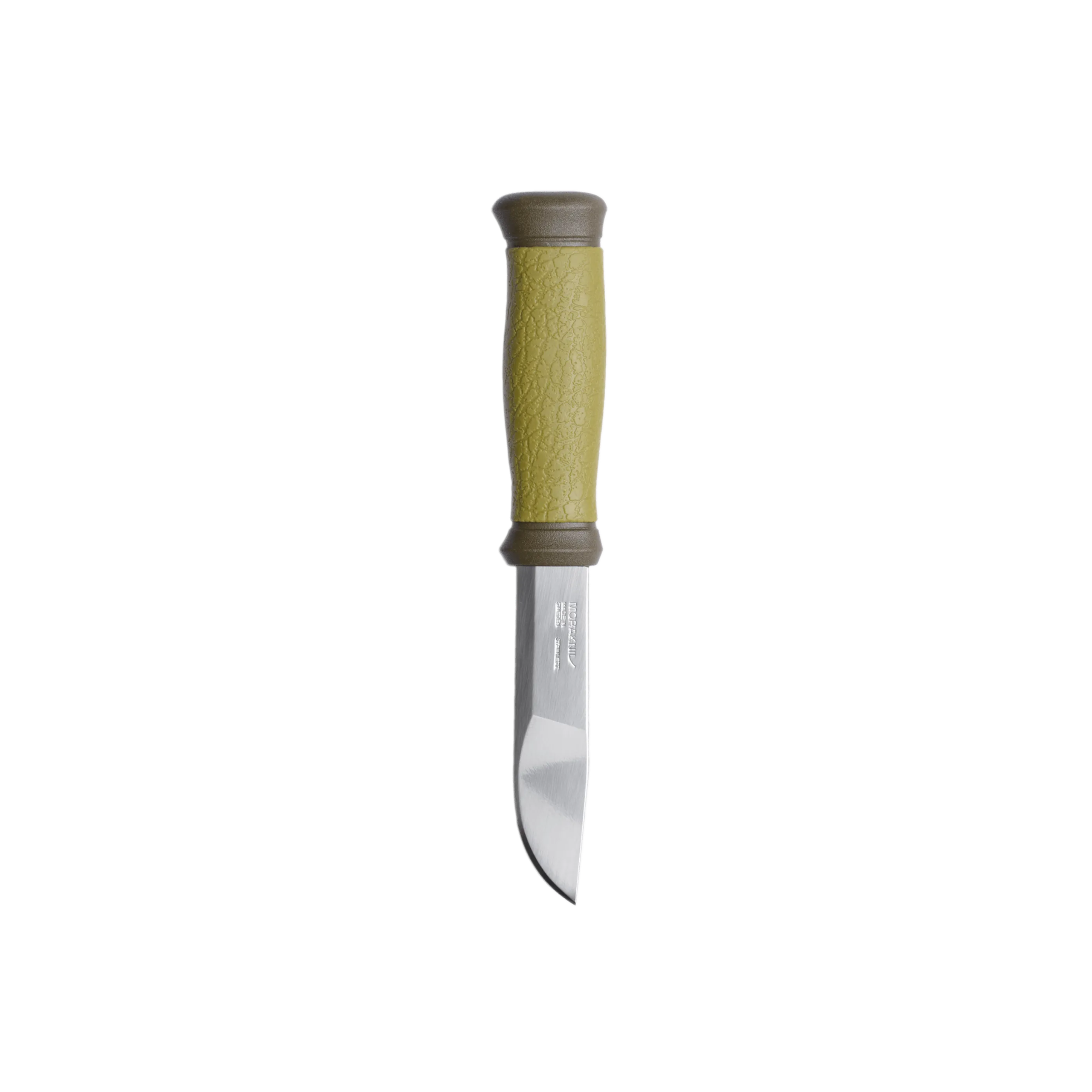

Scandi Grind – with micro bevel

Morakniv’s signature grind, where the edge is ground with a flat bevel all the way down and finished with a micro bevel that makes it less fragile and gives better edge retention.Total edge angle:

23° (11.5 per side) for blades up to 2.5 mm thick, and 27° (13.5 per side) for blades thicker than 2.5 mm.The micro bevel measures about 35–45° in total and 0.05–0.5 mm high.

Best for:

- Outdoor and bushcraft

- Craft and woodcarving

- All-round use

Knife models with Scandi Grind:

Garberg, Companion, Bushcraft, Mora 2000, Lok, Wit, Finn, Basic.Note: our micro bevel is not the same as the American-style secondary bevel – they have completely different characteristics and areas of use.

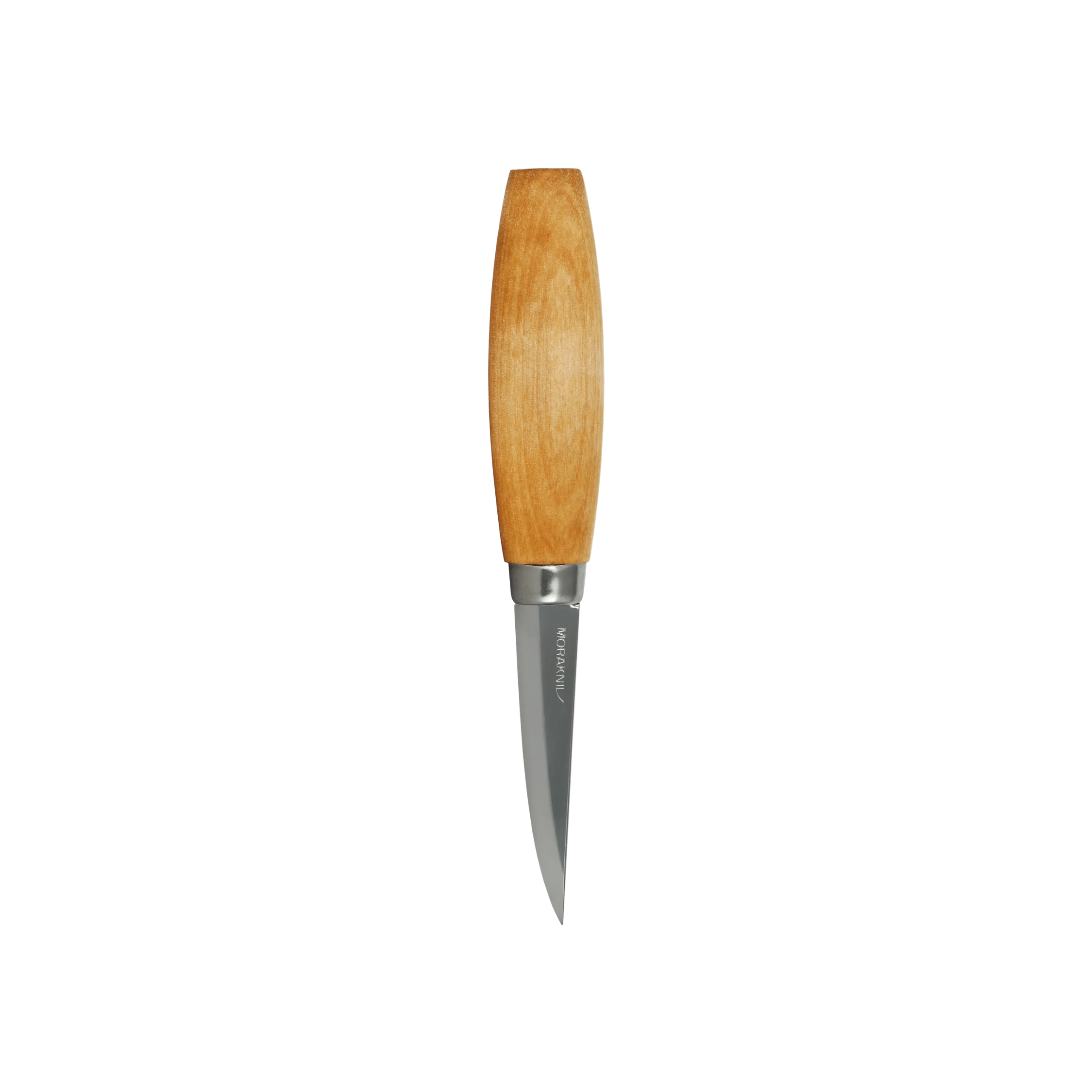

Scandi Grind Zero – without micro bevel

The same basic profile as Scandi Grind, but without the micro bevel. This makes for a sharper, more aggressive edge – perfect for woodworking, but also more delicate and demanding to maintain.Total edge angle: Typically 23° (11.5 per side) for blades up to 2.5 mm thick, and 27° (13.5 per side) for blades thicker than 2.5 mm – this also applies to Pro Precision and Carving Basic with 2 mm blades.

Best for:

- Woodcarving and fine woodworking

- Tasks where maximum sharpness and precision are prioritized

Knife models with Scandi Grind Zero:

Carving knives 105, 106, 120, 122 as well as Pro Precision and Carving Basic.

Other grinds

There are several types of grinds that we do not offer on our knives today, but which may appear in the future:Convex grind.

A slightly rounded grind from the edge up towards the blade, giving a strong and durable edge. Common on axes (sometimes called “axe grind”), survival knives, and popular among bushcrafters in North America.Hollow grind / concave grind (Cozzini grind).

The blade sides are slightly concave, producing a very thin and sharp edge but less robust construction.Knife indentations (Granton-style).

Oval recesses along the blade side that reduce vacuum when slicing foods like cheese or potatoes.

Regrinding the Edge to Suit Your Needs

We grind our knives to be ready for their intended use. If you want to adapt the edge for other tasks, you can regrind it yourself. A popular modification among enthusiasts is a convex or “scandivex” grind, often on models like Garberg, for improved feathersticking and lighter batoning.If you want a Morakniv with a convex grind, you will either need to modify it yourself, buy a modified version from a knifemaker, or purchase from a retailer that offers such grinding services.

Always finish by stropping to remove any burrs. If you don’t have a strop, the back of a leather belt works well, preferably with a little polishing paste such as Autosol chrome polish.

Read more: How to sharpen your knife

For most of the 20th century, each blade was ground by hand by skilled stone grinders. It required both strength and precision, and an experienced grinder could sharpen up to 900 knives in a single day. Grindstones were in short supply during both World Wars, and factories often had to buy used stones from others. The work was tough and wet.

In the early 2000s, automation and robotics took over much of the repetitive work. This freed up time for fine adjustments and quality control, but the principle remains the same as a century ago: every edge must be ground to perfection, adapted to the knife’s intended use.

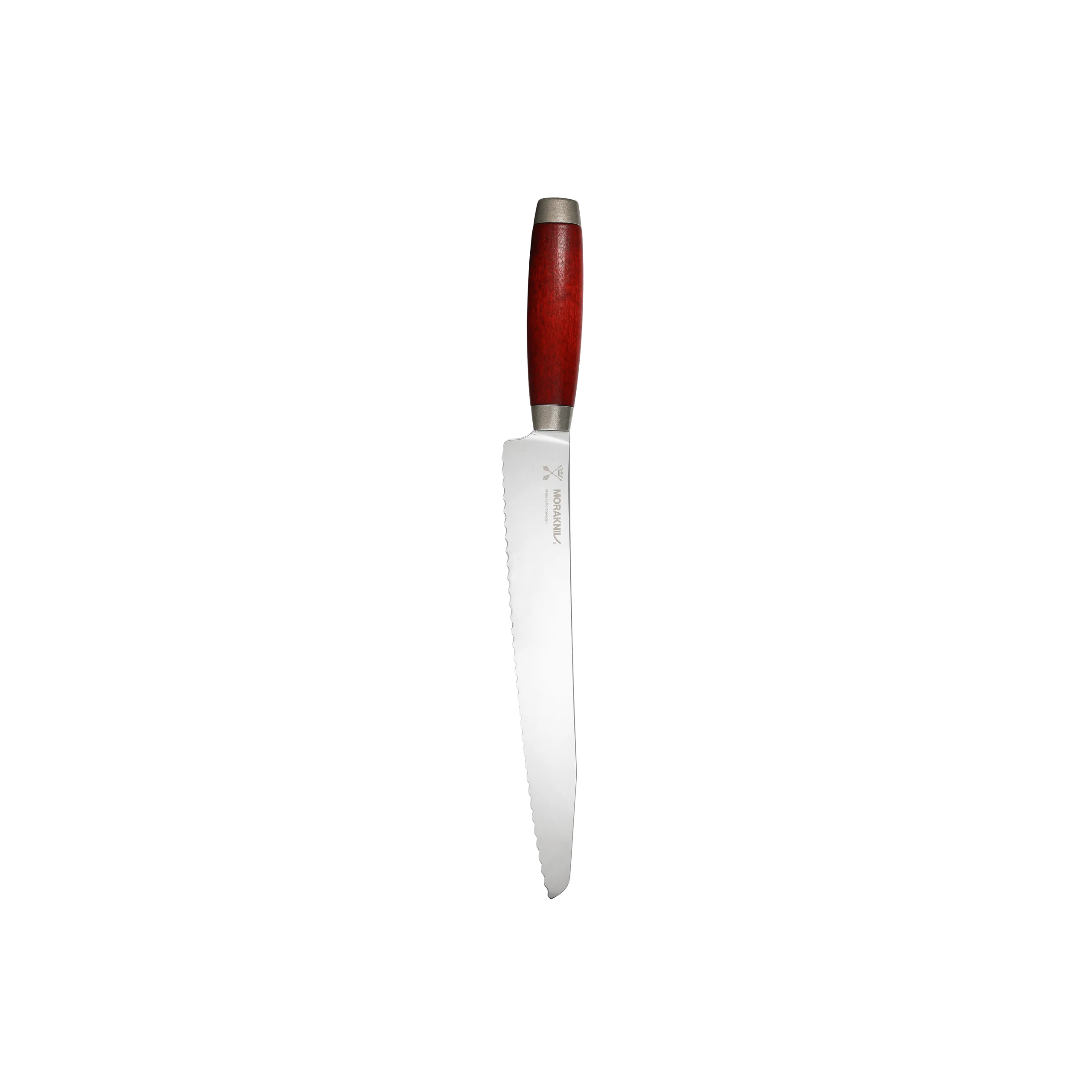

Serrated edge

The edge has small, regular teeth that cut efficiently through fibrous or tough materials.Total edge angle: Varies depending on tooth depth and model.

Best for:

- Bread and baked goods

- Rope, textiles, and fibrous materials

- Emergency situations where fast cutting is crucial

Knife models with serrated edge:

Classic 1891 Bread Knife, Companion Rescue SRT Safe (S), Companion SRT (S), Companion Spark Emergency (partially serrated blade), Pro Rope Knife, Bushcraft BlackBlade SRT (S)

Full Flat Grind

The blade is ground evenly from the spine all the way down to the edge. This provides low friction and long, clean cuts.Total edge angle:

Between 27° and 36°, depending on the knife series.Best for:

- Cooking and slicing

- Long, clean cuts both indoors and outdoors

- A balance between strength and cutting ability

Knife models with Full Flat Grind:

Rombo, Hunting knives (except Kansbol, Eldris, and the gut opener).

Profile-ground

A grind developed for cutting through meat and hide with minimal friction.Total edge angle:

23° for blades ≤ 2.5 mm / about 27° for blades > 2.5 mm.Best for:

- Hunting and fishing

- Cutting through meat, bone, and hide

- Outdoor and all-round use

Knife models with profile-ground:

Kansbol, Eldris, Mora 2000.