Knowing how to sharpen knife properly is one of the most important parts of knife care. A sharp knife is not only more effective – it’s also safer to use. With the right sharpening process and maintenance, the knife edge glides through food or material without effort, reducing the risk of slipping.

Find the Right Sharpening Tool

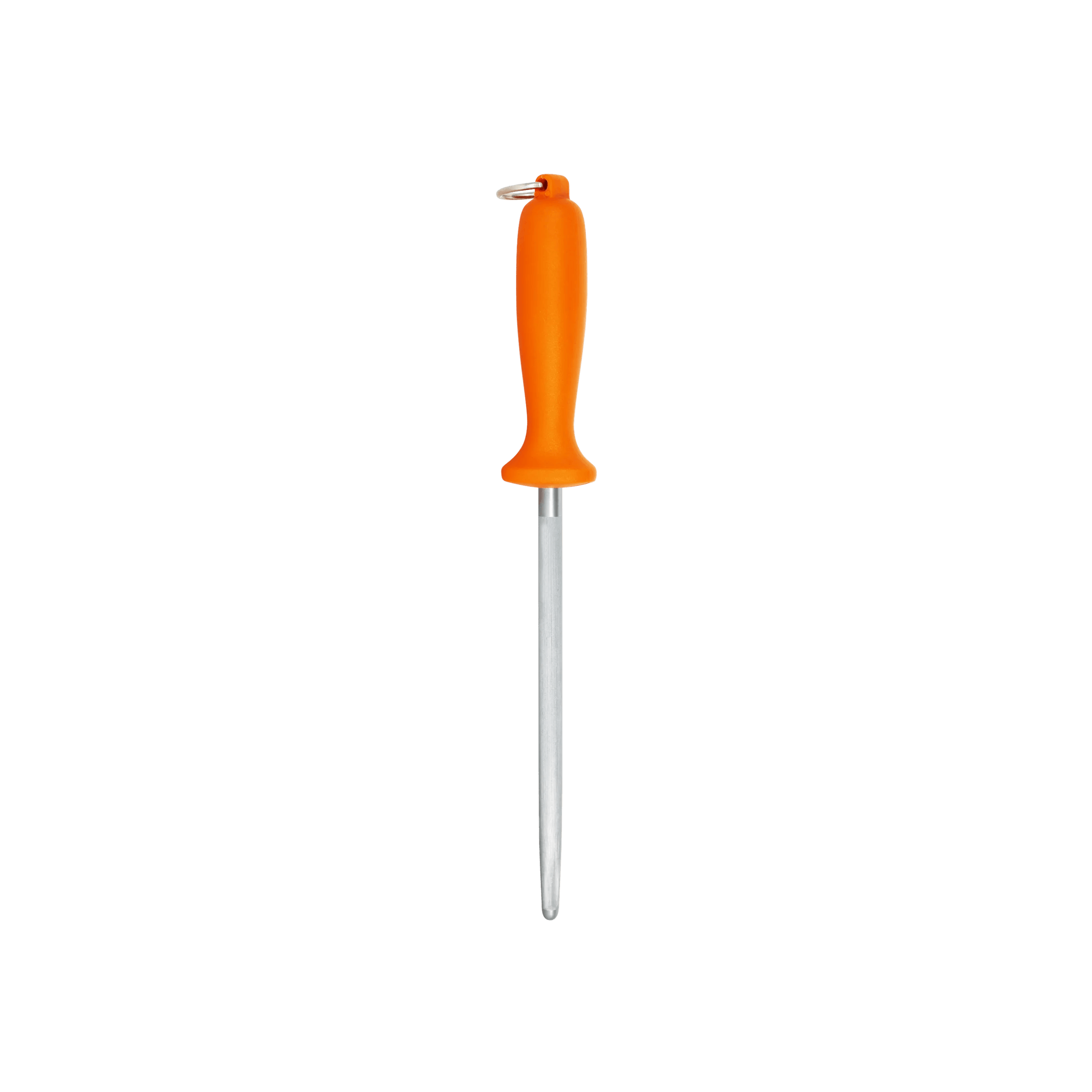

Sharpening and maintenance go hand in hand. If you care for your knife, the blade edge will last longer and perform better. This is especially true for kitchen knives that are used daily. With the right tool and correct angle, you can sharpen knives quickly while preserving the steel.- Sharpening steel / honing rod. Used to realign the edge to a central position without grinding down the blade or removing unnecessary material. Perfect for daily maintenance to prolong a knife’s life. A polished steel is gentle and helps you keep a consistent angle along the entire edge. Coarse steels can be used for tougher jobs, but they require more skill and control.

- Sharpening stones. Remove a small amount of material to restore sharpness when the knife edge has become dull. Available in different grits and materials – for example, diamond stones that are effective for sharpening even hard steels, including carbon steel and stainless.

- Professional knife sharpener / electric sharpener. With the Tormek T-1 Morakniv 1891, you can precisely set the sharpening angle and achieve even bevels along the entire blade of your kitchen knives, finishing with a honing wheel for a razor-sharp edge.

Sharpening Steel for Daily Edge Maintenance

A sharpening steel or honing rod is not for grinding but for keeping the blade edge aligned. Every time you cut, the very edge bends slightly. With a few strokes on the steel, the knife edge is centered again.How to use a sharpening steel:

- Hold the knife blade at the correct angle.

- With your non-dominant hand holding the steel, slowly drag the knife from heel to tip.

- Switch to the opposite direction and repeat on the other side of the edge.

- Finish lightly for a smooth surface.

Preparation Before Sharpening

Before you start sharpening:- Clean the knife. Wipe off grease and dirt so the sharpening process gives a smooth surface.

- Check sharpness. Try slicing paper or tomatoes; a dull blade will snag.

- Choose the right angle. Check the product page of your knife at our website to find its recommended bevel angle.

- Decide how much to sharpen. Do you need a full rebuild of the edge bevel or just a quick touch-up with a steel?

4 Common Mistakes

Wrong angle. A shallow angle gives a fragile blade edge, too steep makes a dull knife.Too much pressure. Wears away steel and makes it harder to maintain a consistent angle – light strokes make for a wicked edge.

Uneven strokes. Inconsistent movement across the entire blade leaves parts sharp and others dull.

One side only. Both sides of the whole edge must be worked evenly, otherwise you’ll end up with an uneven bevel.

Tormek T-1 Morakniv 1891 – Professional Sharpening of kitchen knives at Home

Sometimes a dull blade needs more than a honing rod. When your knife no longer reaches the desired sharpness, it’s time for a complete sharpening process.The Tormek T-1 Morakniv 1891 is an electric sharpener developed for home kitchens, based on the same technology as Tormek’s professional systems.

- Exact angle every time. Adjustable between 8° and 22° per side, so you always sharpen at the correct angle.

- Gentle on the steel. The fine diamond wheel works slowly, removing material only where needed while avoiding overheating.

- Honing process. The honing wheel removes the burr and polishes the very edge to a razor-sharp edge.

- Versatile. Handles most kitchen knives, from small paring knives to large chef’s knives, in carbon steel, stainless, and even ceramic.

Find the Right Angle

With the Tormek T-1 Morakniv 1891 you can set the angle between 8° and 22° per side and achieve the same result every time. The best way to recreate an existing angle is to use the marker method: color the bevel, make a test stroke, and adjust until the color is removed evenly along the entire bevel.Recommended Total Angles for Different Knives

- Wood carving knives: 27° (total angle) – the recommended angle for our carving knives. With their Scandi Grind Zero, the edge becomes too fragile if the angle is reduced towards 20°, so 27° provides the best balance between sharpness and durability.

- Fillet and vegetable knives: 25–30° – a good balance between sharpness and durability.

- Chef’s and kitchen knives: 30–40° – versatile for many tasks, from slicing vegetables to cutting meat.

- Hunting and outdoor knives: 23–35° – makes the edge tough enough for demanding tasks.

- Butcher’s knives: 25–45° depending on intended use.

Sharpening Technique – How to Sharpen Knife

Whether you use sharpening stones, a honing rod or an electric sharpener like Tormek T-1, the basics are the same:- Hold the knife blade at the correct angle.

- Slowly drag the knife from heel to tip, keeping the edge facing the stone.

- Switch in the opposite direction and repeat on the other side for a balanced edge.

- Apply light pressure.

- Feel for the burr along the top edge; remove it with a honing process (steel, leather strop, or honing wheel).

Safety tips:

- Work on a stable surface, like a wood block or cutting board.

- Keep your fingers away from the edge.

- Always follow the instructions for your sharpening tool.

- With machine sharpening: use water cooling and avoid sparks.

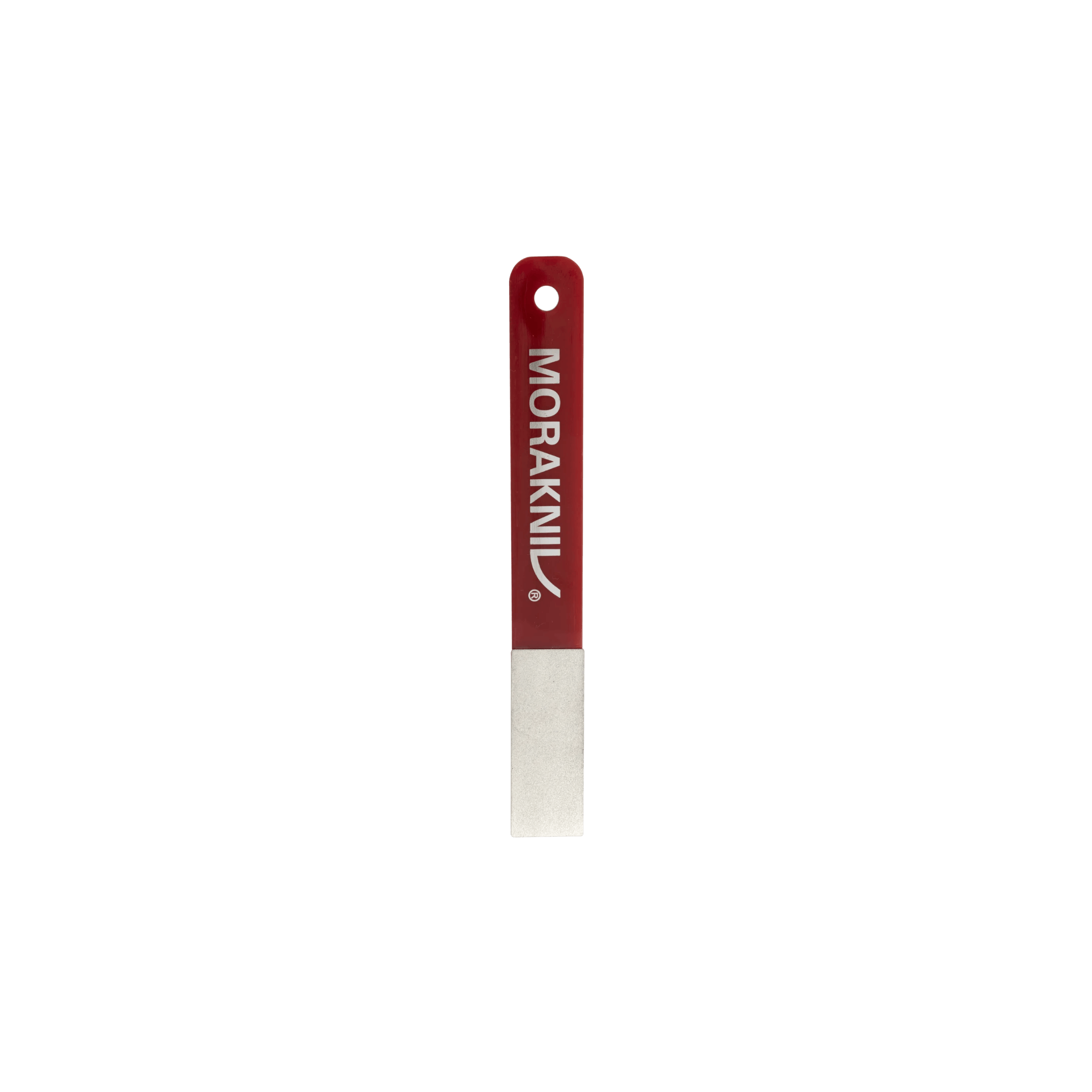

Whetstones and Diamond Stones – Sharpening by Hand

When the knife feels dull, you’ll need sharpening stones. This is the most versatile way to build a wicked edge free hand.Diamond Stone L Fine. Small, light and with a grit size of 600, it restores a sharp edge quickly and easily. Works for both knife blade and axe.Diamond Stone 26 Fine. Same surface in a longer format for more control, supplied with a protective leather sheath.