Every Morakniv is made in our factory in Östnor, just outside Mora, Sweden, and has been since 1891. Here, more than 130 years of knife-making tradition is combined with modern technology. Because we oversee every step of the process—from the first press to final packing—we can ensure lasting quality. Take a look behind the scenes.

The Steel: The Heart of the Knife

It all starts in the steel storage. We use several grades of steel, each selected for a specific purpose. Our Swedish stainless steel is strong, durable, and resistant to corrosion. We also use high-carbon steel from Germany and France. The French carbon steel is laminated, with a high-carbon core and softer carbon steel on the outer layers, providing excellent toughness and long-lasting edge performance.

Press hall: 7000 blades per hour

In the pressing hall, you can hear the heartbeat of our factory. A 120-ton press stamps out two knife blanks every second, adding up to 7,000 per hour. Each blade is shaped with specific geometry based on how the knife will be used.

Heat Treatment: The Secret Behind the Blade's Performance

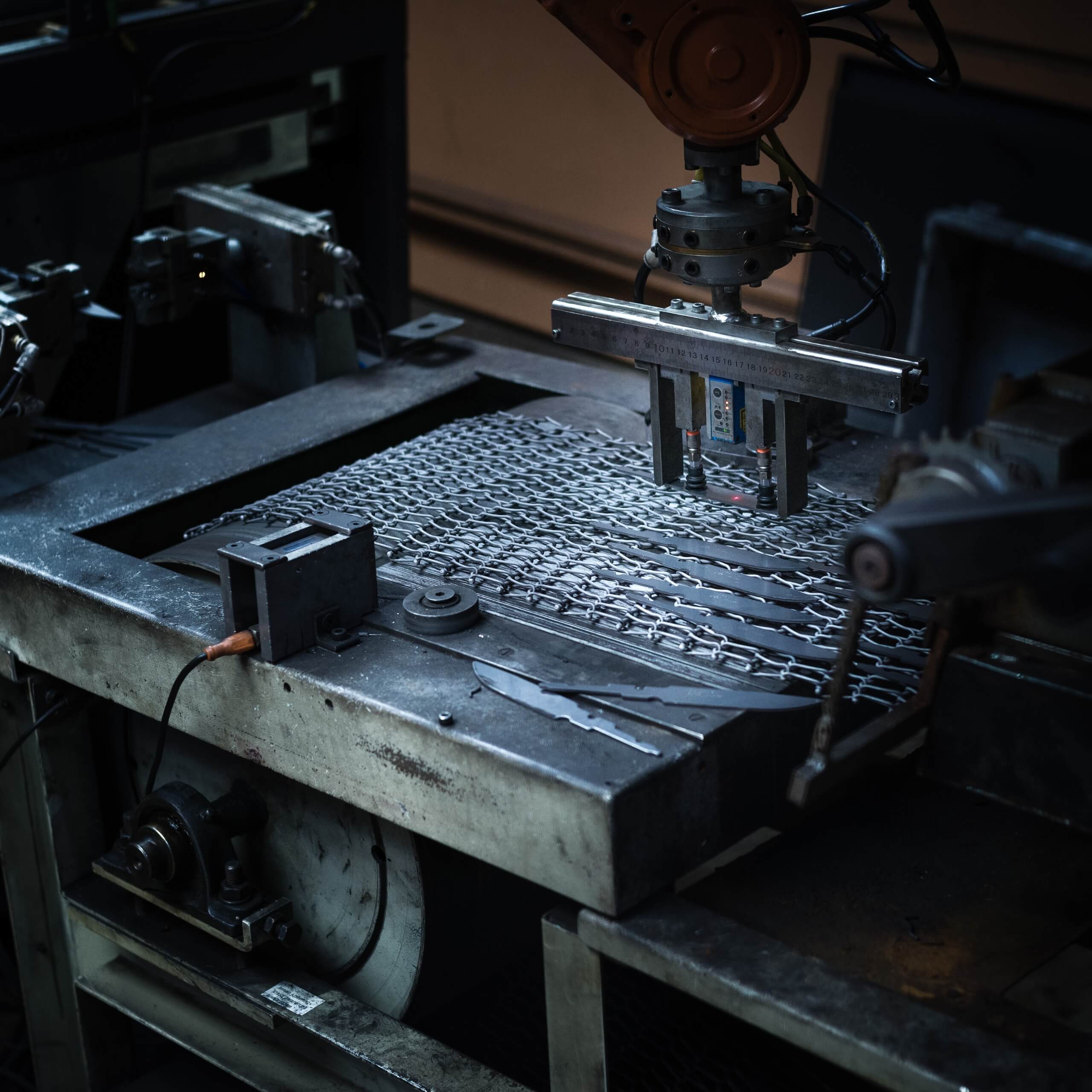

The blades undergo heat treatment to boost hardness, toughness, and edge retention. We use two separate hardening ovens for stainless and carbon steel. A robot loads the blades into the furnace, then rapidly cools them to harden the steel. The exact process is a closely held secret—our recipe for achieving the sharpness, strength, and flexibility that define a Morakniv. Hardness is measured in Rockwell C, and each batch is carefully checked to ensure values stay within the approved range.

Grinding: 3 Million Knives a Year

Next comes grinding. More than 3 million knives are ground each year, with over 90% handled by robotic grinding cells. The spine, sides, and edge of each blade are shaped with precision. The grind profile—including our signature Scandi grind—is selected based on the knife’s intended use.

Polishing for a Razor-Sharp Finish

After grinding, the blades are polished for their final finish. A rough polish removes burrs and surface irregularities. Then, each blade is buffed to a mirror-like shine and sharpened to a razor edge. The transformation is clear: from dull and raw to bright and sharp. Sharpness is tested continuously to ensure every knife meets our standard. Our polishing machines handle more than 10,000 knives a day.

Wooden Handles: Assembled by Hand

Knives with wooden handles begin in our climate-controlled wood chamber. Swedish birch and curly birch from Finland are stored under optimal conditions to prevent cracking. The wood is milled and turned before being hand-assembled—a tradition we’ve preserved since 1891. About 10% of our knives feature wooden handles, with blades attached using either glue or rivets, depending on the model.The rest of our handles are injection molded, either manually or in automated production cells named Egglund and Gabriel. Knife sheaths are also molded here. The polymer is heated to over 200°C (392°F), injected into precision molds, cooled, and solidified into tough, ergonomic handles—with a hard inner core and soft, grippy exterior.